Tyres Instructions

Navigate every road with confidence – follow KMS Tyres' instructions for optimal performance.

Useful Details For Tyres

We have a fleet of over 25 limousines ready for lorem ipsum dolor sit amet.

Tyre Statistics

Tyre Pressures

UK Tyre Law

Looking After Tyres

Load Index and Speed Rating

EU Tyre Labelling

Writing On My Tyres

Replacing Tyres in Axle Pairs

Tyre Statistics

In the pursuit of impeccable service, motorists seek nothing short of excellence – a blend of superior quality, undeniable value, expert guidance, and the ease of local accessibility when addressing tyre concerns.

Acknowledging the vast array of tyre options saturating the market today, our team of tire connoisseurs stands poised to navigate you through the labyrinth of choices, ensuring a bespoke selection tailored to your vehicle’s needs and your driving preferences from our extensive catalogue of premier tyre brands.

To facilitate your decision-making process, we’ve curated comprehensive insights into various tyre brands, tread patterns, and performance attributes, empowering you to make informed decisions when selecting the perfect replacement tyre, seamlessly aligning with your vehicle type and driving style.

Moreover, compliance with legal mandates is paramount; thus, it’s imperative to equip your vehicle with tyres of the correct type and size, meticulously abiding by regulations governing tread depth and overall tyre condition. With a legal threshold of 1.6 millimetres for minimum tread depth, enforced uniformly across the central three-quarters of the tyre’s circumference, adherence to these standards ensures not only legal compliance but also optimal safety on the road.

Considering that your tyres serve as the sole point of contact between your vehicle and the road, the significance of selecting the right tyre type cannot be overstated. Cultivating a routine of fortnightly tyre inspections – encompassing pressure checks and overall condition assessments, including the spare tyre – is not merely advisable but imperative to safeguarding both vehicle performance and passenger safety.

Tyre Pressures

Maximizing the longevity of your tyres, enhancing vehicle safety, and optimizing fuel efficiency all hinge upon the precision of tyre pressures. These pressures, quantified in pounds force (PSI) or BAR pressure, reflect the volume of air expertly infused into the tyre’s inner lining.

Responsibility for ensuring these pressures align with manufacturer specifications rests firmly with the vehicle owner, necessitating regular checks and adjustments, ideally conducted every fortnight.

The significance of maintaining optimal tyre pressures cannot be overstated, underscored by three pivotal factors: safety, economy, and environmental impact. Under-inflated tyres pose a risk of overheating, compromising vehicle handling, while over-inflated counterparts impair traction and accelerate wear and tear, demanding premature replacements. Furthermore, the inefficiencies of incorrect pressures manifest in increased fuel consumption, perpetuating unnecessary carbon emissions and environmental strain.

Vigilance in pressure monitoring is paramount, as air loss, though subtle, persists at a rate of up to two pounds monthly, exacerbated during warmer climates. Armed with the recommended pressure values, readily accessible in vehicle handbooks or affixed within the vehicle’s technical documentation, drivers are urged to employ tyre pressure gauges during cold tyre assessments, ensuring adherence to prescribed standards. Additionally, for vehicles burdened with additional loads, reference to the vehicle handbook is indispensable for determining the appropriate loaded tyre pressures, safeguarding both performance and safety.

UK Tyre Law

Understanding UK tyre law is crucial for every vehicle owner, as compliance ensures not only legal adherence but also optimal safety on the road. UK legislation mandates the precise fitting of tyres tailored to your vehicle type and usage, emphasizing both correct type and size, alongside adherence to manufacturer-recommended inflation pressures to uphold safety standards.

With a legal tread depth limit set at 1.6 millimetres, spanning the central three-quarters of the tyre’s circumference, preemptive tyre replacement before reaching this threshold is advised, with many manufacturers recommending replacement at 3 millimetres. The implications of tread wear on safety are profound, particularly in wet conditions, where a mere 1.6-millimetre depth disparity translates to an additional two car lengths required to halt at 50 mph compared to treads measuring 3 millimetres.

Vigilant tyre maintenance not only averts potential penalties, including three penalty points and fines up to £2,500 for tyres worn beyond legal limits but also underscores a commitment to road safety. Additionally, compliance extends to ensuring uniformity in tyre construction types across the same axle, precluding the mixing of radial and cross-ply tyres. While mixing brands and patterns within the same construction type is permissible, adherence to vehicle-specific recommendations outlined in the handbook is paramount, ensuring compatibility and performance integrity.

Looking After Tyres

Caring for your tyres demands a meticulous regimen, urging a bi-weekly inspection encompassing both pressure levels and external integrity.

The imperative of maintaining optimal tyre pressures transcends mere precaution, embodying a trifecta of paramount concerns: safety, economic efficiency, and environmental stewardship. Underinflated tyres risk overheating and compromise road handling, while overinflated counterparts incur accelerated wear and fuel inefficiencies. Correct pressures not only ensure fuel economy but also mitigate carbon emissions, fostering a greener footprint.

External scrutiny is equally pivotal, as cuts, protrusions, or irregularities, often borne from encounters with road hazards, mandate swift assessment by tire specialists to forestall potential catastrophic failures.

Furthermore, vigilant oversight of wheel alignment is indispensable, counteracting the adverse effects of kerbing or pothole encounters which jeopardize tire longevity and wear patterns. Recognizing the aftermath of emergency maneuvers like abrupt braking, prompt tire evaluation is advised to mitigate any potential flat-spot formations.

Ultimately, the onus rests with the driver to uphold legal mandates dictating precise tire fitting and inflation, safeguarding both personal safety and environmental preservation. Tire wear is multifaceted, influenced not only by age and mileage but also by external factors such as road conditions and driving habits. Misaligned wheels exacerbate wear differentials, underscoring the necessity for regular maintenance to ensure optimal tire performance and longevity.

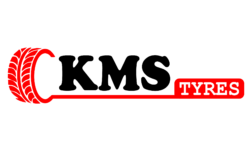

Load Index and Speed Rating

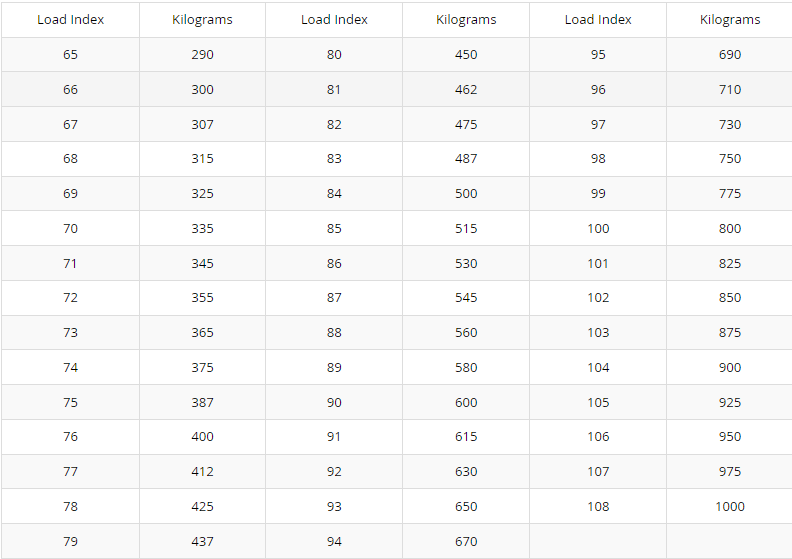

Embedded within the rubbered contours of tyres lie enigmatic codes, each a testament to their formidable load-bearing prowess and velocity capabilities.

Consider the cryptic insignia “91V”:

The numerical prefix, 91, signifies the tire’s impressive threshold for bearing weight, translating to a remarkable 615 kilograms of load-bearing capacity, a testament to its structural robustness and engineering precision.

Meanwhile, the alphabetical suffix, V, unfurls a tapestry of velocity potential, denoting a formidable speed rating of 240 kilometers per hour, or approximately 149 miles per hour, emblematic of its capacity to navigate the asphalt expanse with unparalleled agility and poise.

In essence, the load index serves as a numerical beacon, intricately linked to the tire’s maximal load-carrying capacity, synergistically complemented by its corresponding speed symbol. Together, they unravel the tire’s narrative of strength and speed, poised to conquer every terrain with unparalleled confidence and performance excellence.

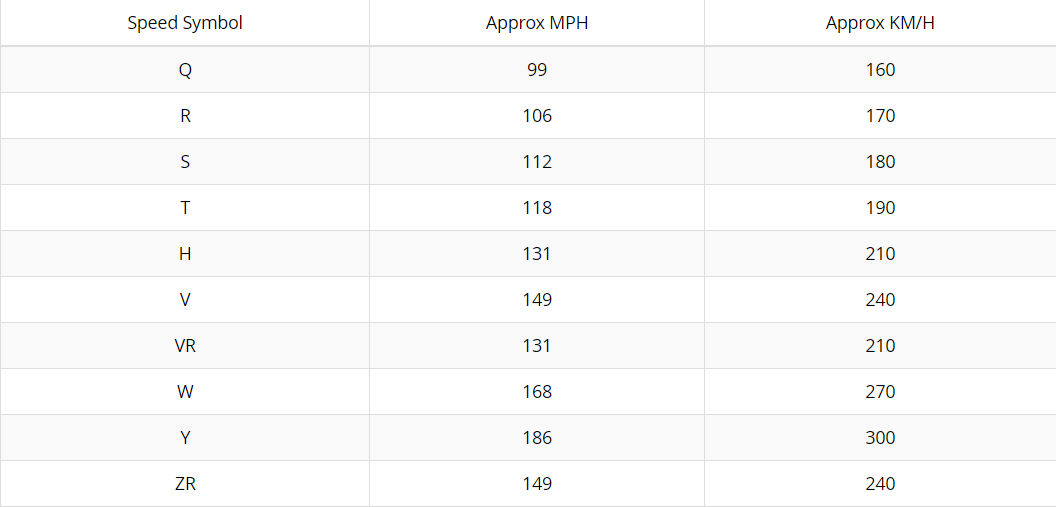

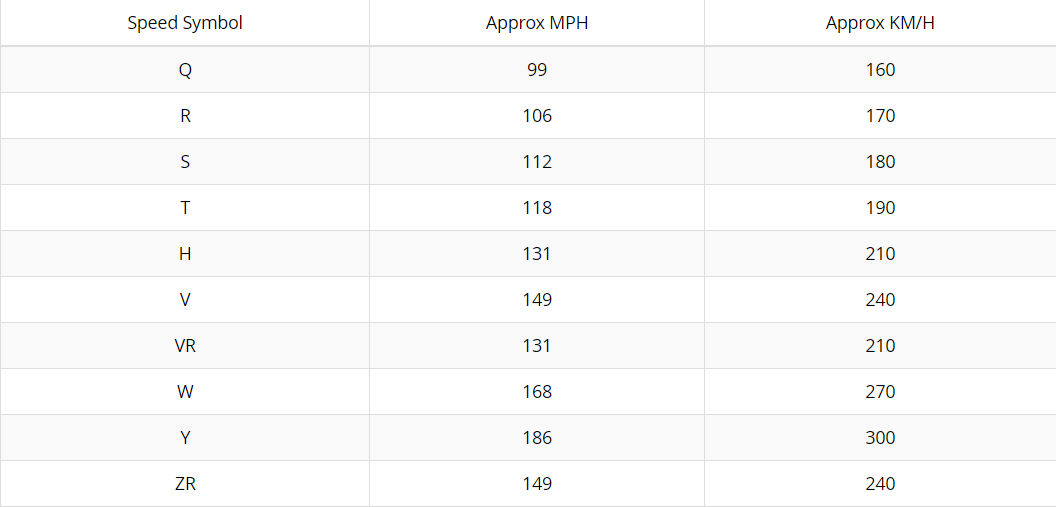

The velocity emblem serves as a herald of the tire’s dynamic capabilities, signifying the velocity at which it gracefully transports the designated load associated with its load index. For precise insights into speed rating specifications, refer to the comprehensive details provided below.

The velocity emblem serves as a herald of the tire’s dynamic capabilities, signifying the velocity at which it gracefully transports the designated load associated with its load index. For precise insights into speed rating specifications, refer to the comprehensive details provided below.

The velocity emblem serves as a herald of the tire’s dynamic capabilities, signifying the velocity at which it gracefully transports the designated load associated with its load index. For precise insights into speed rating specifications, refer to the comprehensive details provided below.

The velocity emblem serves as a herald of the tire’s dynamic capabilities, signifying the velocity at which it gracefully transports the designated load associated with its load index. For precise insights into speed rating specifications, refer to the comprehensive details provided below.

EU Tyre Labelling

Understanding EU Tyre Labelling

Our team of tire experts is dedicated to assisting you in selecting the ideal tire for your vehicle and driving preferences. The EU Tyre Label serves as a valuable tool, providing confidence in our recommendations and empowering you to make informed comparisons between different tires. Since November 2012, all car tires, SUV tires, van tires, and 4×4 tires have been graded across three crucial categories:

Fuel Efficiency

A tire’s rolling resistance, which determines fuel consumption, is a key consideration. Grade A tires can potentially decrease fuel usage by up to 7.5% compared to grade E tires.

Wet Grip

Tires with superior wet grip offer shorter braking distances on wet surfaces, significantly enhancing safety. Grade A tires may reduce braking distances by up to 30% compared to grade E tires.

Exterior Noise

External noise levels, graded A, B, or C, contribute to overall driving comfort. The new EU Tyre Label, introduced in May 2021, aims to streamline the grading system, focusing on Fuel Efficiency and Wet Grip, while simplifying External Noise grading.

Three Peak Mountain Snowflake (3PMSF) Symbol

Eligible tires may feature the 3PMSF symbol, denoting exceptional winter performance. Winter tires equipped with this symbol exhibit significantly improved braking distances on snowy roads compared to summer tires.

Ice Grip Symbol

Tires with the Ice Grip symbol offer enhanced braking performance on ice, making them suitable for severe climates with snow and ice-covered roads. However, their performance may vary in wet conditions or warmer climates.

QR Code

Located in the top right corner of the label, the QR code provides instant access to additional tire information and product sheets when scanned with a smartphone or tablet. Please note that while the EU Tyre Label provides valuable insights, it’s essential to consider individual driving conditions and preferences when selecting tires.

Our team of tire experts is dedicated to assisting you in selecting the ideal tire for your vehicle and driving preferences. The EU Tyre Label serves as a valuable tool, providing confidence in our recommendations and empowering you to make informed comparisons between different tires. Since November 2012, all car tires, SUV tires, van tires, and 4×4 tires have been graded across three crucial categories:

Fuel Efficiency

A tire’s rolling resistance, which determines fuel consumption, is a key consideration. Grade A tires can potentially decrease fuel usage by up to 7.5% compared to grade E tires.

Wet Grip

Tires with superior wet grip offer shorter braking distances on wet surfaces, significantly enhancing safety. Grade A tires may reduce braking distances by up to 30% compared to grade E tires.

Exterior Noise

External noise levels, graded A, B, or C, contribute to overall driving comfort. The new EU Tyre Label, introduced in May 2021, aims to streamline the grading system, focusing on Fuel Efficiency and Wet Grip, while simplifying External Noise grading.

Three Peak Mountain Snowflake (3PMSF) Symbol

Eligible tires may feature the 3PMSF symbol, denoting exceptional winter performance. Winter tires equipped with this symbol exhibit significantly improved braking distances on snowy roads compared to summer tires.

Ice Grip Symbol

Tires with the Ice Grip symbol offer enhanced braking performance on ice, making them suitable for severe climates with snow and ice-covered roads. However, their performance may vary in wet conditions or warmer climates.

QR Code

Located in the top right corner of the label, the QR code provides instant access to additional tire information and product sheets when scanned with a smartphone or tablet. Please note that while the EU Tyre Label provides valuable insights, it’s essential to consider individual driving conditions and preferences when selecting tires.

Writing On My Tyres

Tyre Markings

Deciphering the inscriptions on your tires can be bewildering. The sidewall of a standard tire is adorned with numerous codes and numbers, serving to specify its size, physical attributes, and manufacturing details. While some of these tire markings may seem insignificant to drivers, others play a crucial role in selecting suitable replacement tires.

For those in search of new tires, it is advisable to acquaint oneself with the following tire inscriptions.

Replacing Tyres in Axle Pairs

In the intricate realm of tire maintenance, the significance of replacing tires in axle pairs emerges as a cornerstone of vehicular integrity and performance optimization. While the inconvenience of tire punctures is a well-known adversary, the imperative of swift tire replacement extends beyond mere repair considerations. It encompasses the vital concept of maintaining harmony within axle pairs, where the balance between two wheels sharing an axle is paramount.

Axle pairs, comprising the tandem of wheels on each axle, operate in tandem, sharing loads and stresses as they navigate the varied terrains of the road. Just as a seesaw seeks equilibrium, so too must the wheels of an axle pair synchronize their movements for optimal performance. However, in the real-world theater of driving, achieving absolute parity between wheels is a rarity. Factors such as tire inflation levels introduce variances in effective wheel diameter, consequently affecting rotation rates and steering dynamics.

Consider the analogy of two individuals running side by side: a child and an adult. The child, with shorter strides, must exert greater effort to match the speed of the adult, reflecting the differential in rotation rates between tires on an axle pair. This incongruity in rotation engenders an uneven force distribution across the axle, resulting in premature wear on vital components such as suspension bushings and bolts.

Moreover, the importance of matching tread patterns between tires within an axle pair cannot be overstated. Engineered to efficiently channel water away from the tire surface, tread patterns dictate the tire’s ability to maintain crucial contact with the road, especially in inclement weather conditions. Misalignment of tread patterns or installation of tires in opposite directions disrupts this vital function, compromising handling and accelerating tire wear.

In the realm of 4-wheel drive vehicles, the integrity of all tires becomes even more pivotal, as any imbalance in one tire reverberates across the entire drivetrain. Thus, a recommendation is made to replace all 4×4 tires simultaneously upon the degradation of one, ensuring uniformity in traction and grip.

Despite the absence of punctures, tire replacement may be necessitated by tread wear below legal minimums, as indicated by the renowned 20p coin test. While the legal minimum tread depth is 1.6mm, prudence dictates replacement at 3mm, particularly in wet weather conditions where the risk of aquaplaning escalates exponentially.

For those embarking on the quest for new tires, the journey begins with a seamless online browsing experience, facilitated by our comprehensive Tyre Finder tool. Whether navigating through the intricacies of tire specifications or seeking expert guidance, our team of specialists stands ready to ensure that each tire selected is imbued with the essence of excellence, perfectly tailored to meet the demands of your vehicle and driving aspirations.

Tyre Markings

Tyre SIze

Speed Rating

Load Index

Data of Manufacture

Reinforced

Run Flat

Homologation

Tyre Markings

The enigmatic inscriptions adorning your tires often present a labyrinth of codes and symbols, imbued with both cryptic mystique and vital significance. Within this intricate tapestry lie the clues to unraveling the tire’s dimensions, characteristics, and lineage, offering a glimpse into its inherent essence and manufacturing pedigree. While some of these tire markings may seem shrouded in obscurity to the untrained eye, others serve as indispensable signposts guiding the discerning driver in the quest for the perfect replacement tire.

For those embarking on the odyssey of tire procurement, a mastery of the following tire markings is paramount, offering a beacon of clarity amidst the labyrinthine corridors of tire specifications and selection.

Tyre SIze

In the intricate lexicon of tire specifications, one of the fundamental elements lies in discerning the tire size, an alphanumeric sequence emblazoned upon the sidewall of the tire. Among the myriad variations that grace the roads of the UK, the ubiquitous 205/55R16 stands as a common manifestation, yet the diversity within this realm necessitates meticulous scrutiny of both existing tires and vehicle handbooks to ensure precise compatibility.

Delving deeper into the tapestry of tire dimensions, the tire width takes precedence, with the initial three digits proclaiming the tire’s girth in millimeters, delineating its span from sidewall to sidewall with exacting precision. Meanwhile, the aspect ratio, revealed by the subsequent digits, bestows insight into the tire’s profile height as a percentage of its width, an invaluable metric in understanding its structural integrity and performance potential.

At the core of tire construction lies the radial designation, denoted by the resolute letter ‘R’, signifying the tire’s innovative composition with cord plies oriented perpendicular to the direction of travel. This radial configuration imbues the tire with unparalleled strength and resilience, a hallmark of modern tire engineering that epitomizes durability and performance.

Rounding out the tire size ensemble, the final two digits unveil the wheel diameter, serving as both a descriptor of the wheel rim’s size and the tire’s diameter from bead to bead. A tire adorned with the numeral 16, for instance, finds its destined abode upon a 16-inch wheel rim, a symbiotic marriage of tire and wheel ensuring harmonious operation on the roadways.

Speed Rating

Within the intricate tapestry of tire specifications lies the illustrious speed rating, a revered symbol denoted by a letter of the alphabet, serving as a testament to the tire’s formidable prowess on the asphalt expanse. Embarking upon a journey of validation through a rigorous battery of tests, tires earn their speed rating by showcasing unwavering fortitude in maintaining set speeds over prolonged durations, thus earning their stripes in the realm of velocity.

Enter the realm of tire speed ratings, where each letter bears the weight of expectation, signifying the tire’s maximum speed capability. From the resolute ‘R’ heralding a maximum speed of 106 mph, to the pinnacle of velocity epitomized by other letters in the alphabet, each speed rating serves as a beacon guiding drivers towards optimal performance and safety.

Yet, in the labyrinth of tire selection, uncertainty may cast its shadow. Fear not, for the vehicle handbook stands as a bastion of knowledge, offering guidance to those in search of the perfect speed rating to complement their driving endeavors. Remember, veering towards a lower speed rating than recommended could potentially compromise not only your tire’s performance but also jeopardize the sanctity of your insurance coverage. Thus, let prudence and wisdom guide your selection, ensuring that every journey unfolds with the grace and assurance bestowed by the perfect tire speed rating.

Load Index

Amidst the labyrinth of tire specifications lies the esteemed load index, a beacon of insight into a tire’s prodigious weight-bearing capabilities. This numerical code, discreetly nestled between the tire size marking and the speed rating, serves as a testament to the tire’s fortitude in shouldering formidable loads with grace and resilience.

Venture into the realm of load index scrutiny, where each digit holds the key to unlocking the tire’s maximum load capacity. From the illustrious 91, denoting a formidable 650kg load capacity, to the myriad other numerical permutations, each load index embarks upon a journey of discovery, revealing the tire’s unparalleled aptitude in supporting vehicular mass with unwavering strength.

Yet, amidst the pursuit of tire perfection, heedfulness prevails. While it may not transgress the bounds of legality, the wisdom of adhering to manufacturer-recommended tire specifications resonates with prudence. Venturing into the realm of lower speed ratings or load indexes, or mixing tire construction types, although not prohibited, may compromise the symbiotic harmony between tire and vehicle. Thus, consulting the sacred tome of vehicular knowledge, the vehicle handbook, emerges as a beacon of guidance, illuminating the path towards tire selection wisdom and ensuring each journey unfolds with the assurance of optimal performance and safety.

Data of Manufacture

Amidst the intricate tapestry of tire lore lies the venerable record of its genesis – the Date of Manufacture, a testament to precision engineering and adherence to the highest standards of safety. Commencing with the illustrious acronym DOT, signifying compliance with the rigorous safety benchmarks set forth by the Department of Transport, this alphanumeric saga unveils a narrative of tire birth and provenance.

Embark upon a journey of deciphering tire ancestry, where the first eight characters serve as a cryptic serial code, unraveling the tire’s lineage and the hallowed halls of its production facility. Yet, the pièce de résistance lies in the final four digits, meticulously displayed within a petite window, offering a glimpse into the tire’s age.

Behold the chronicle of tire vintage, where the initial two digits unveil the week of its inception, spanning from the inaugural week of the year to its triumphant conclusion at week 52. Meanwhile, the latter pair of digits bestows the year of origin upon the tire, an epoch-defining moment captured in a succinct numerical guise. Thus, a tire marked 1315 proudly proclaims its genesis in the 13th week of the illustrious year 2015.

Yet, as with all things, time exacts its toll, and tires age with each passing moment, a process hastened by the rigors of infrequent vehicular usage. Should the annals of your tire’s manufacture reveal a span in excess of six years, the prudent course of action beckons – a thorough examination to ensure their continued roadworthiness. Thus, let the saga of tire lineage and age guide you on the path to vehicular safety and tire longevity, ensuring that each journey unfolds with the assurance of impeccable craftsmanship and unwavering reliability.

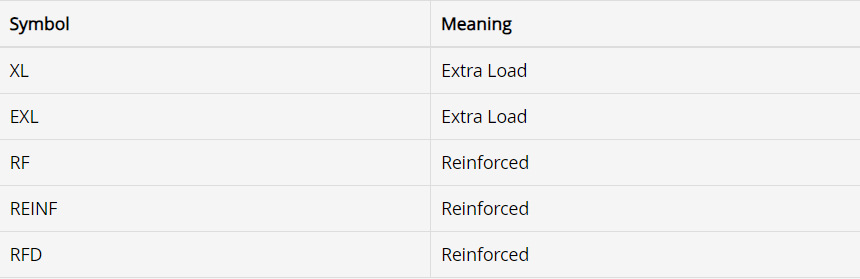

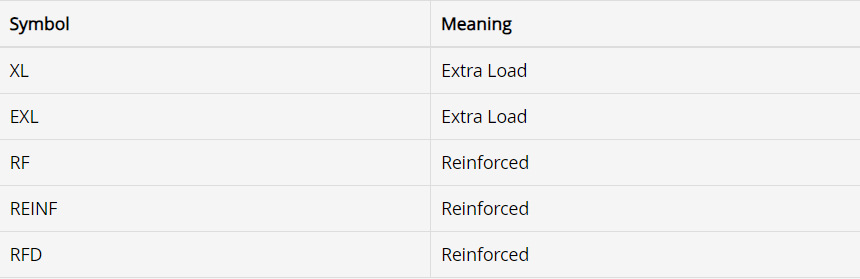

Reinforced

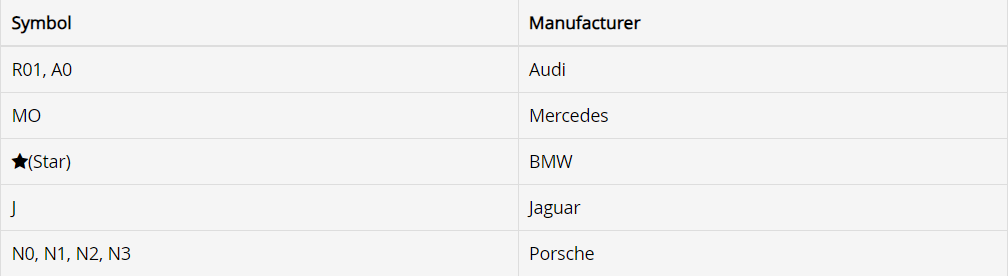

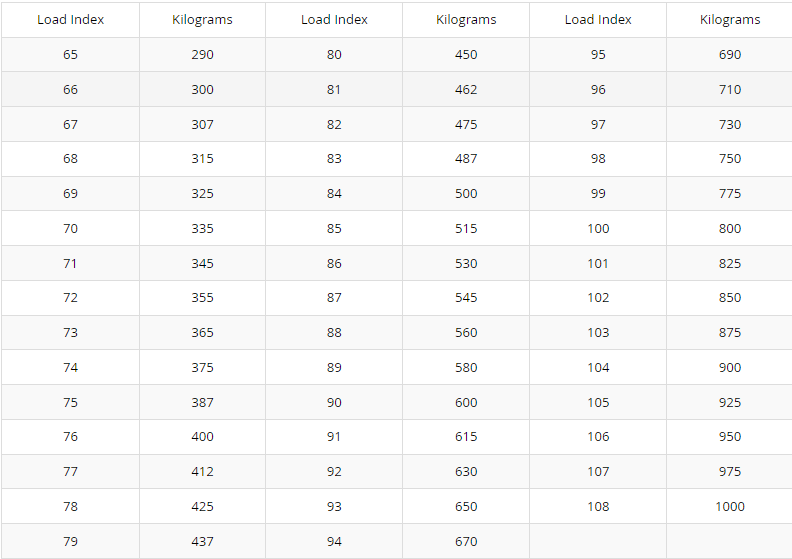

Tires boasting a higher load index are typically labeled to signify their reinforcement for carrying additional weight. While specifics may differ among manufacturers, be on the lookout for the following symbols, which indicate the tire’s reinforced construction:

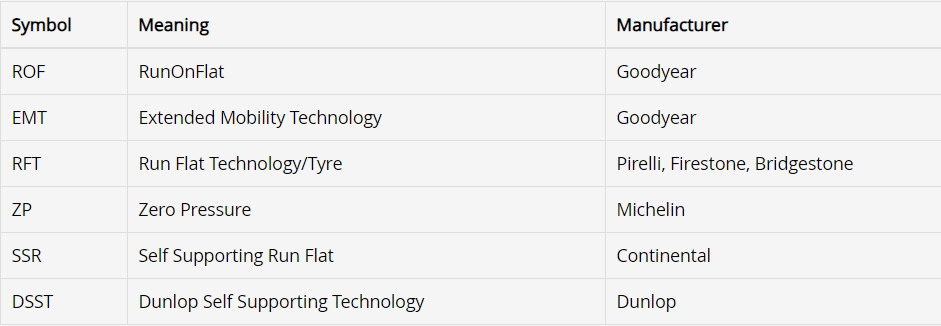

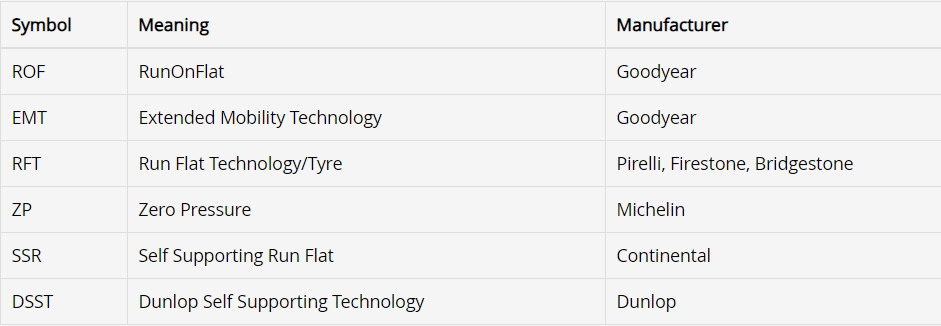

Run Flat

Run-flat tires are engineered with reinforced sidewalls, enabling them to support the vehicle’s weight in the event of a pressure loss, such as a puncture. This feature allows the tire to remain operational for a limited period, allowing you to safely reach a suitable location for tire replacement. Various tire manufacturers utilize distinct markings to denote run-flat tires.

Homologation

In the intricate realm of tire maintenance, the significance of replacing tires in axle pairs emerges as a cornerstone of vehicular integrity and performance optimization. While the inconvenience of tire punctures is a well-known adversary, the imperative of swift tire replacement extends beyond mere repair considerations. It encompasses the vital concept of maintaining harmony within axle pairs, where the balance between two wheels sharing an axle is paramount.

Axle pairs, comprising the tandem of wheels on each axle, operate in tandem, sharing loads and stresses as they navigate the varied terrains of the road. Just as a seesaw seeks equilibrium, so too must the wheels of an axle pair synchronize their movements for optimal performance. However, in the real-world theater of driving, achieving absolute parity between wheels is a rarity. Factors such as tire inflation levels introduce variances in effective wheel diameter, consequently affecting rotation rates and steering dynamics.

Consider the analogy of two individuals running side by side: a child and an adult. The child, with shorter strides, must exert greater effort to match the speed of the adult, reflecting the differential in rotation rates between tires on an axle pair. This incongruity in rotation engenders an uneven force distribution across the axle, resulting in premature wear on vital components such as suspension bushings and bolts.

Moreover, the importance of matching tread patterns between tires within an axle pair cannot be overstated. Engineered to efficiently channel water away from the tire surface, tread patterns dictate the tire’s ability to maintain crucial contact with the road, especially in inclement weather conditions. Misalignment of tread patterns or installation of tires in opposite directions disrupts this vital function, compromising handling and accelerating tire wear.

In the realm of 4-wheel drive vehicles, the integrity of all tires becomes even more pivotal, as any imbalance in one tire reverberates across the entire drivetrain. Thus, a recommendation is made to replace all 4×4 tires simultaneously upon the degradation of one, ensuring uniformity in traction and grip.

Despite the absence of punctures, tire replacement may be necessitated by tread wear below legal minimums, as indicated by the renowned 20p coin test. While the legal minimum tread depth is 1.6mm, prudence dictates replacement at 3mm, particularly in wet weather conditions where the risk of aquaplaning escalates exponentially.

For those embarking on the quest for new tires, the journey begins with a seamless online browsing experience, facilitated by our comprehensive Tyre Finder tool. Whether navigating through the intricacies of tire specifications or seeking expert guidance, our team of specialists stands ready to ensure that each tire selected is imbued with the essence of excellence, perfectly tailored to meet the demands of your vehicle and driving aspirations.